With the advent of nanotechnology, high energy metal particles are prodcued at the nanoscale level. Renewed interest on the addition of nanoscale metal particles (i.e., metal nanoparticles) as fuel additives to liquid fuels has instigated several research to evaluate their influence on evaporation, combustion, and emission characteristics. It is well known that addition of nanoparticles will alter the fuel physical properties, which inturn affects the atomization characteristics of the fuel. The change in atomization characteristics will have a cascading effect on the combustion characteristics. Hence, a sound knowledge of atomization process will help to gain insights on the combustion characteristics. Therefore, at MSTF, we have focused the research efforts on the influence of nanoparticles on the liquid fuel spray features at near nozzle and far downstream locations through laser/optical diagnostic techniques.

Nanoscale fuel additives:

Spray characteristics @ “Elevated ambient conditions”

Biofuels - Straight Vegetable Oil (Canola Oil)

The spray characteristics of alternative biofuels like straight vegetable oil (canola oil) using air blast atomizer. The effect of flow rate of primary air, secondary air, and fuel flow rate. The near nozzle spray characteristics is visualized through shadowgraph optical diagnostic technique. The droplet characteristics further downstream are measured using the phase Doppler anemometry.

Select publication:

- G. Yu, O. Askari, F. Hadi, Z. Wang, H. Metghalchi, K. Kumaran, R. Sadr, “Theoretical prediction of laminar burning speed and ignition delay time of Gas-to-Liquid fuel”, ASME J Energy Resources Technology, 139, 022202 (1-6), 2017.

- Kumaran K, Anoop K and Sadr R, “Effect of nanoparticles on the fuel properties and spray performance of aviation turbine fuel”, J Energy Resources Technology, 139, 032201 (8 pages), 2017.

- Kumaran K., and Reza Sadr, “Influence of nanoparticles on spray performance of alternative jet fuels (GT2016-57778)", ASME Turbo Expo 2016, Seoul, June 13-17, 2016.

- Ayman Y., Kumaran K., and Reza Sadr, “Spray visualization of alternative aviation turbine fuel embedded with Metallic Nanoparticles”, Proc. 10th Pacific Sym. on Flow Visualization and Image Processing, June 15-18, Naples, Italy, paper ID: 110, 2015.

Selected Publications:

- Kumaran K, and Sadr R, “The effect of alumina nanoparticles as fuel additives on the spray characteristics of gas-to-liquid jet fuels”, Experimental Thermal and Fluid Science, 87, 93-103, 2017.

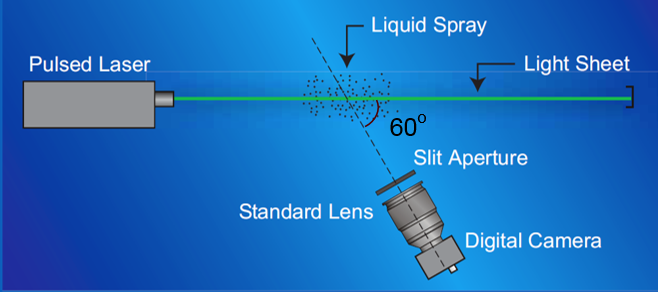

@ Atmospheric ambient conditions (Preliminary study): An academia-industry consortium research was started between Rolls-Royce UK, German Aerospace Center (DLR) Germany, and MSTF-Texas A&M University at Qatar (TAMUQ). The objective of TAMUQ part was to study the change in spray characteristics due to the change fuel physical properties between the conventional jet fuel (Jet A-1) and the Synthetic paraffinic kerosene fuel (GTL). The droplet size and velocity at the macroscopic level of the spray were measured using the Global Sizing Velocimetry (GSV from TSI Inc.,) and the spray characteristics at microscopic levels were measured using the phase Doppler anemometry (PDA from Dantec Dynamics) at atmospheric ambient conditions. In addition to these techniques, the shadowgraph technique was also employed to gain additional insights on the change in near nozzle spray features. At atmospheric conditions, the spray characteristics of GTL and Jet A-1 fuels were comparable.

Phase Doppler Anemometry, Dantec Dynamics

- Kumaran Kannaiyan and Reza Sadr, "Experimental investigation of spray characteristics of alternative aviation fuels" Energy Conversion and Management, 88: 1060-1069, 2014

- Kumaran Kannaiyan and Reza Sadr, "Effect of fuel properties on spray characteristics of alternative jet fuels using Global Sizing Velocimetry", Atomization and Sprays, 24 (7): 575-597, 2014.

Select publications:

However, atmospheric ambient conditions does not truly represent the actual combustor conditions. It is important to have thorough knowledge of the spray characteristics when the volatilization characteristics of the fuels are significantly different. This led to the follow-up research proposal to investigate the spray performance at high pressure & high temperature ambient conditions - NPRP grant: “In-depth Characterization of Spray and Combustion Performance of Alternative Jet Fuels at Gas Turbine Combustor Conditions”

A high-pressure high -temperature spray rig with optical access was built to investigate the spray performance at elevated conditions. highlights of spray chamber are:

- Made of 316 SS steel – ASME Boiler & Pressure vessel Code

- Three quartz optical windows for laser diagnostic tools. Additional window option to view from the bottom for cross sectional imaging

- Max. working pressure /Temperature for optical windows: 30 bar / 200oC

- Upgradable to ‘combustion’ vessel with modifications to optical windows (OW) & sealsThe experimental facility is shown below.

Global Sizing Velocimetry, TSI Inc.

High-Pressure High-Temperture Spray experimental facility:

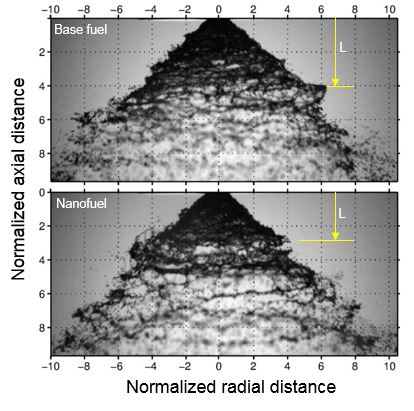

Sample shadowgraph Images: